-

Company

Leading the global atomization intelligent manufacturing, accelerating the world's transition to a quality life, MOKI is willing to provide all partners with a one-stop solution for globally leading electronic atomization technology, and jointly write a beautiful future with technology.

-

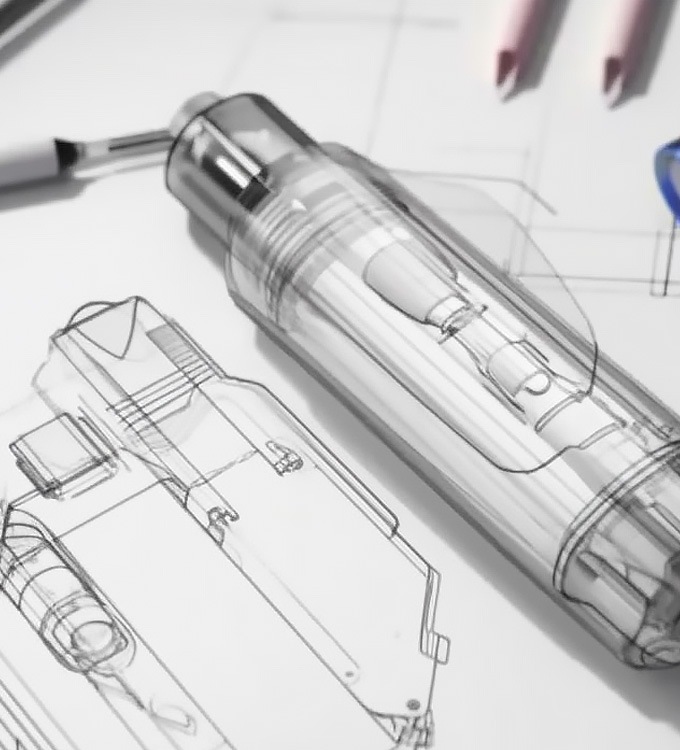

ODM/OEM

MOKI is your expert partner for premium vape OEM & ODM services. We handle everything from R&D to mass production for your disposable and pod vape brands...